GOMA ENGINEERING P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to GOMA ENGINEERING P.LTD.

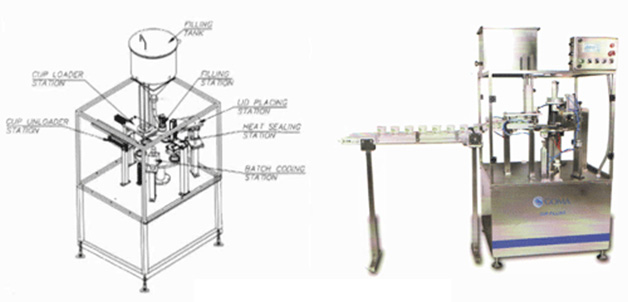

Rotary Type Cup Filling And Sealing Machine

Goma manufactured Pneumatic Cum Mechanical operation CUP FILLING & SEALING MACHINE, with template SS construction and PLC controller based.

Goma also manufactures automatic cup and cone filling machines for Ice-cream applications. (Rotary / Linear)

The machine is PLC based which is easy for maintenance and operation, more accurate.

The basic machine consists of the following stations:

- Cup de-stacking station

- Filling station

- Lid placing station

- Lid sealing station

- Cup discharge station

- Indexing driving system

Cup And Cone Filling Machine

Get complete solutions for filling and packing of ice–cream and frozen desserts with our automatic PLC based Cup and Cone filling machine.

Rugged and robust sanitary design is what makes our Cup and cone filling machine stand apart from other machines in the market today.

It is Flexible and compatible for any variety of Ice-cream and Frozen desserts filling.

Functional Stations:

- Cup/cone de-stacking – Station includes both cup /cone stack holder from which the cup/cone is de-stacked and dropped in the cup-ring with the help of vacuum cups.

- Chocolate spraying – Initial phase of the filling section where chocolate is stuffed at both the end of the Cone & Cup.

- Ice Cream Filling station – Ice cream mixture is filled in the Cone/Cup.

- Chocolate Topping – In this liquid chocolate is arrayed on top of the ice-cream.

- Fruit and nut feeder station – Proper proportion of nut or dry fruits are scattered over the chocolate topping.

- Lid placing station – At the end of the filling process with the help of the vacuum cup the lid for cup/cone is placed over it with maximum precision.

- Cone Pressing Station – It is only active when cone filling is in process it helps in folding the cone wrapper.

- Cup / Cone Discharge – The finished product is discharge with the help of Pneumatic pistons.

Aseptic Plastic Pouch Filling Machine

The Aseptic Filling machine is used to fill sterilized product like Milk, Flavoured Milk, Drinking Yoghurt, Juices, etc., in pouches / pillow / brick for long shelf life of 30-180 days at ambient temperatures.

In conventional method pasteurized milk is packed and stored under refrigerated conditions before consumption which has shelf life of 3-4 days.

With Aseptic Plastic Pouch Filling machine, sterilized product is filled at ambient temperature under aseptic condition at 25°C – 30°C in plastic pouches of 3/5 layers coextruded film. This gives shelf life of 30-45 days for a 3 layer film and 60-90 days for a 5 layer film. The product can be kept under normal room temperature and requires no cold transport and storage.

Goma’s Aseptic Plastic Pouch Filling Machine is a high speed machine which is operated automatically through a PLC. The machine is double head and sterilization of the film is done by H₂O₂ (Hydrogen Peroxide and UV Treatment). It is under positive air pressure to maintain aseptic conditions within the machine. The machine is provided with inbuilt CIP system

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.